Understanding the Role of Certifications in the Pharma Industry

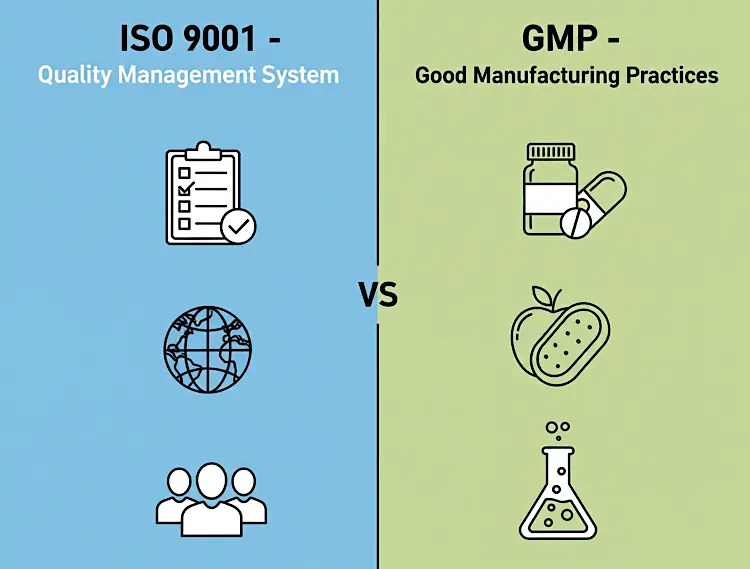

Certifications play a crucial role in the pharmaceutical industry because medicines directly impact human health and safety. Unlike other manufacturing sectors, pharma companies must follow strict regulatory frameworks to ensure that products are safe, effective, and consistent. WHO-GMP and ISO certifications are two commonly discussed standards, but their purpose, scope, and regulatory value are often misunderstood.

Many pharma businesses assume that ISO certification alone is sufficient to establish quality credibility. However, this misunderstanding can lead to serious compliance gaps, rejected exports, and regulatory penalties. To build a strong foundation, it is essential to clearly understand what WHO-GMP and ISO certifications are designed to achieve and how they differ in real-world pharmaceutical operations.

Key Focus Areas of Pharma Certifications

- Patient safety as a priority: Pharma certifications are designed to ensure medicines do not cause harm due to contamination, incorrect dosage, or poor manufacturing practices. WHO-GMP directly addresses these risks, while ISO supports systems that indirectly improve operational consistency.

- Regulatory compliance and legal acceptance: Certifications determine whether a pharmaceutical unit can legally manufacture and supply medicines. WHO-GMP is often a legal requirement, whereas ISO is a voluntary quality management standard.

- Market trust and brand credibility: Certifications build confidence among doctors, distributors, and regulators. WHO-GMP signals regulatory compliance, while ISO reflects management discipline and process stability.

Key Areas Where AI and Automation Impact Pharma Production

Enhancing Efficiency and Reducing Errors

AI and automation streamline operations, reduce human intervention, and minimize errors. From precise formulation measurements to robotic packaging, these technologies ensure consistency and accuracy.

Main Points :

- Automated Formulation Systems : Robots and smart dispensers prepare compounds with precise dosages, eliminating variability.

- Predictive Analytics for Equipment : AI predicts equipment failures and schedules maintenance before downtime occurs.

- Digital Batch Records : Automated recording systems ensure complete traceability and reduce documentation errors.

- Inventory Management : AI-powered tools monitor stock levels, reorder supplies, and prevent shortages.

Additional Points :

- Process Optimization : AI models analyze production data to optimize throughput, reduce waste, and increase yield.

- Energy Efficiency : Automated systems control energy usage in manufacturing plants, reducing operational costs and carbon footprint.

- Faster Production Cycles : Robotics and AI-driven systems accelerate repetitive tasks, speeding up batch production and packaging.