Why India Is Becoming a Global Hub for Injectable Manufacturing

India’s pharmaceutical industry has long been recognized for producing high-quality medicines at cost-effective rates. Over the past decade, injectable drug manufacturing has emerged as one of its fastest-growing segments. From startups to established pharmaceutical brands, companies worldwide are increasingly outsourcing production of sterile injectables to India.

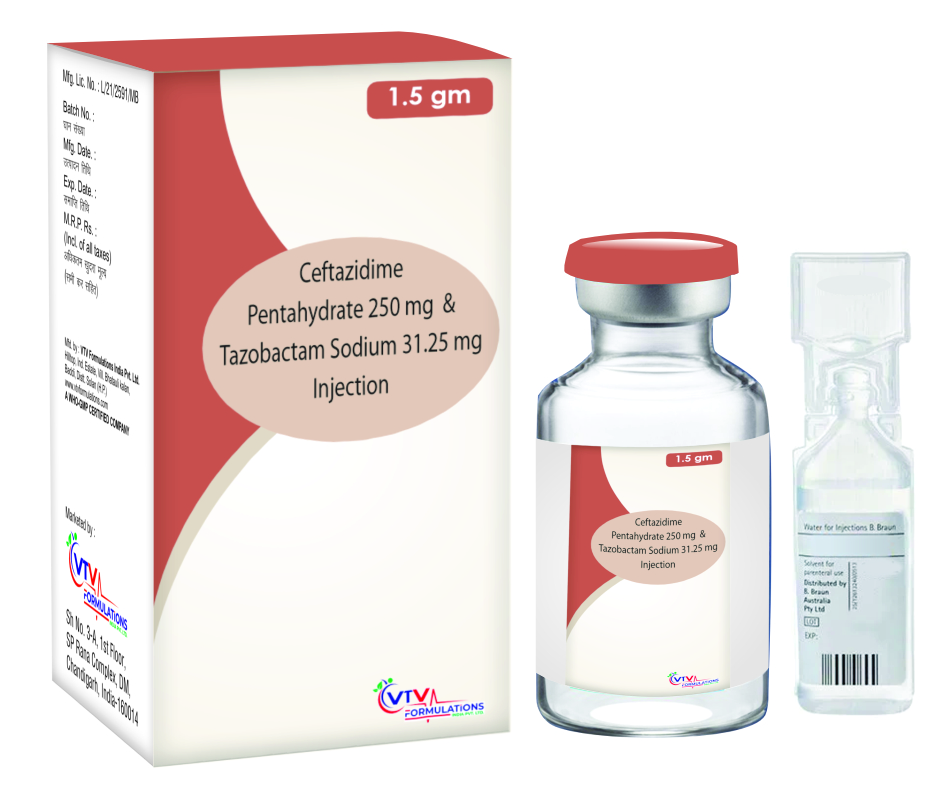

Injectables play a crucial role in modern medicine, especially in critical care, chronic disease management, and hospital-based treatments. These include antibiotics, insulin, oncology drugs, vaccines, and emergency medications. Producing such products requires precise handling, sterile facilities, and strict regulatory compliance. India’s manufacturing ecosystem provides all of this, making it an attractive destination for global pharmaceutical companies.

Key Drivers Behind India’s Rise in Injectable Manufacturing

Several factors have positioned India as a leading choice for third-party injectable production:

- Cost Efficiency: Labor and operational costs in India are significantly lower than in Western countries, allowing manufacturers to provide competitive pricing without compromising quality.

- Regulatory Approvals: Many Indian facilities hold certifications from international regulatory bodies, including US FDA, EMA, WHO-GMP, and ISO. This makes their products export-ready for regulated markets worldwide.

- Advanced Infrastructure: India has invested heavily in specialized pharmaceutical zones and SEZs, ensuring robust infrastructure for aseptic and sterile injectable manufacturing.

- Skilled Workforce: India’s talent pool of pharmacists, chemists, engineers, and regulatory experts ensures meticulous management of complex manufacturing processes.

- Global Logistics Support: The well-established export ecosystem allows manufacturers to meet international delivery timelines efficiently, supporting global supply chains.

This combination of cost advantages, compliance, infrastructure, and talent has made India a preferred destination for pharmaceutical companies seeking reliable third-party injectable manufacturing.

How to Identify and Evaluate the Right Injectable Manufacturer in India

Define Your Product Requirements Clearly

Before searching for a manufacturer, define the exact specifications for your injectable product. Consider factors such as:

- Type of injectable (liquid, lyophilized, prefilled syringe, vial, ampoule)

- Dosage forms and strengths required

- Batch sizes for pilot or commercial production

- Target markets and necessary regulatory certifications

- Packaging and labeling requirements

Having these details in advance helps you filter potential partners more efficiently and ensures they can meet your specific production needs.

Conduct Thorough Research on Manufacturers

Finding the right manufacturer requires careful research. Methods include:

- Attending pharmaceutical expos such as CPHI India or IPHEX

- Searching B2B platforms like IndiaMART or Pharmabiz

- Engaging sourcing agents or industry consultants

- Asking for referrals from industry peers

While evaluating candidates, pay attention to their certifications (WHO-GMP, US FDA, EU-GMP), specialization in injectables, infrastructure for sterile processing, and prior export experience.

Conduct Facility Audits

A site audit—virtual or in-person—provides insights into a manufacturer’s operations. Key areas to examine include:

- Equipment, technology, and automation systems

- Cleanroom classifications and aseptic conditions

- Quality control and microbiology laboratories

- Standard Operating Procedures (SOPs) and documentation practices

- Safety, hygiene standards, and regulatory compliance

Whenever possible, involve a third-party auditor or regulatory expert to validate adherence to global standards.

Start With a Trial Batch

Before full-scale production, request a small trial batch to evaluate:

- Product quality and formulation consistency

- Packaging accuracy and labeling precision

- Delivery timelines and responsiveness

- Communication and transparency in operations

Trial batches reduce risk and allow you to assess a manufacturer’s capabilities before committing to larger volumes.

Negotiate Clear Agreements

Once a manufacturer meets your requirements, establish a comprehensive legal and operational agreement. Include clauses for:

- Pricing and payment terms

- Batch release schedules and quality testing protocols

- Intellectual property ownership

- Confidentiality, liability, and non-compete clauses

A well-structured contract protects both parties and lays the foundation for a long-term collaboration.

Benefits of Outsourcing Injectable Manufacturing to India

Cost-Effective Production Without Compromise

Injectable manufacturing is more complex and expensive than producing tablets or capsules. Indian manufacturers offer cost advantages through lower wages, efficient supply chains, and government incentives, without compromising product quality. This allows pharmaceutical companies to allocate resources to research, marketing, and expansion.

Access to Advanced Manufacturing Facilities

India hosts world-class manufacturing plants with state-of-the-art technology, including:

- Isolator-based aseptic filling systems

- Sterile cleanrooms for injectable production

- Lyophilization units for freeze-dried injectables

- Auto-injector and prefilled syringe assembly lines

These facilities undergo frequent inspections from USFDA, WHO, and other authorities, ensuring compliance with international standards.

Faster Time-to-Market

Experienced Indian manufacturers streamline the production process, from formulation to packaging and dossier preparation, reducing the time between product development and commercial launch. Turnkey services often include trial batches, labeling, and regulatory submissions for both domestic and international markets.

Scalability and Flexibility

Indian manufacturers provide flexible production models, suitable for small pilot batches or large-scale commercial runs. Companies can quickly scale production to meet market demand without investing in new infrastructure, making India an ideal partner for growing businesses and global supply chain diversification.

Regulatory Compliance and Documentation

Indian manufacturers maintain thorough documentation and quality control systems. Certificates of Analysis (COA), Batch Manufacturing Records (BMR), and environmental monitoring logs ensure that products meet regulatory requirements in India and abroad.