A Guide to Finding the Best Third-Party Injection Manufacturers

India has emerged as one of the most trusted and advanced hubs for third-party injectable manufacturing. With state-of-the-art infrastructure, skilled talent, and global-standard certifications, Indian manufacturers produce high-quality injectable medicines for domestic and international markets. Pharmaceutical companies today prefer outsourcing their injectable production to specialized contract manufacturers to reduce costs, minimize operational load, and bring products to market faster. This collaboration model allows brands to expand their offerings without investing heavily in sterile manufacturing facilities, which require precision, automation, and strict environmental controls.

Injectables are among the most sensitive pharmaceutical categories because they involve direct administration into the bloodstream or tissues. This demands exceptional sterility, careful handling, and validated processes. India’s leading third-party injectable manufacturers follow WHO-GMP, ISO, and Schedule-M guidelines to ensure that every vial or ampoule meets rigorous safety and quality parameters. With automated filling lines, purified water systems, sterilization tunnels, depyrogenation systems, and robust quality control labs, these manufacturers maintain the highest standards of injectable production.

Many pharmaceutical companies—from startups to well-established brands—choose third-party manufacturing to reduce overhead costs and speed up product launches. This approach lets businesses utilize the existing expertise and technological infrastructure of experienced manufacturing units. As a result, companies gain access to high-quality injectables without worrying about plant setup, compliance audits, manpower training, or expensive maintenance. With the increasing global demand for cost-effective injectables, India’s third-party manufacturing ecosystem continues to grow rapidly.

Key Benefits of Third-Party Injectable Manufacturing

- Lower Capital Investment: Avoiding the establishment of a sterile unit saves huge investment on equipment, facility design, HVAC systems, and technical manpower, allowing companies to allocate funds toward marketing and expansion.

- Faster Market Expansion: Since the manufacturer already has approved facilities and resources, brands can immediately begin production and launch their injectable range without long setup delays.

- Higher Operational Efficiency: Manufacturers manage raw material procurement, quality testing, formulation, filling, packing, and dispatching, helping companies operate smoothly with reduced workload.

- Better Compliance & Quality Assurance: WHO-GMP certified contract manufacturers follow strict quality procedures, ensuring every batch meets sterility, stability, and safety standards to minimize regulatory issues.

- Focus on Branding & Marketing: Instead of managing complex manufacturing operations, companies can focus on sales growth, doctor engagement, distributor networks, and overall brand-building activities.

Top Factors to Consider When Choosing a Third-Party Injectable Manufacturer

Selecting the right third-party injectable manufacturer is essential for maintaining product quality, brand reputation, and long-term business success. Since injectables require precision and sterility, you must evaluate your manufacturing partner carefully before signing any agreement. A well-chosen manufacturer becomes an extension of your business, helping you deliver safe and effective products to the market.

Below are the most important factors to consider:

-

Certifications & Regulatory Compliance

A reputable manufacturer must hold WHO-GMP, ISO, and other mandatory certifications. These approvals confirm that the facility follows strict guidelines for safety, hygiene, sterilization, and documentation procedures.

-

Manufacturing Infrastructure & Technology

Inspect whether the unit has advanced cleanroom facilities, automated filling lines, high-quality RO/EDI water plants, and validated sterilization systems. Modern machinery ensures consistent sterile manufacturing without manual errors.

-

Product Range & Specialization

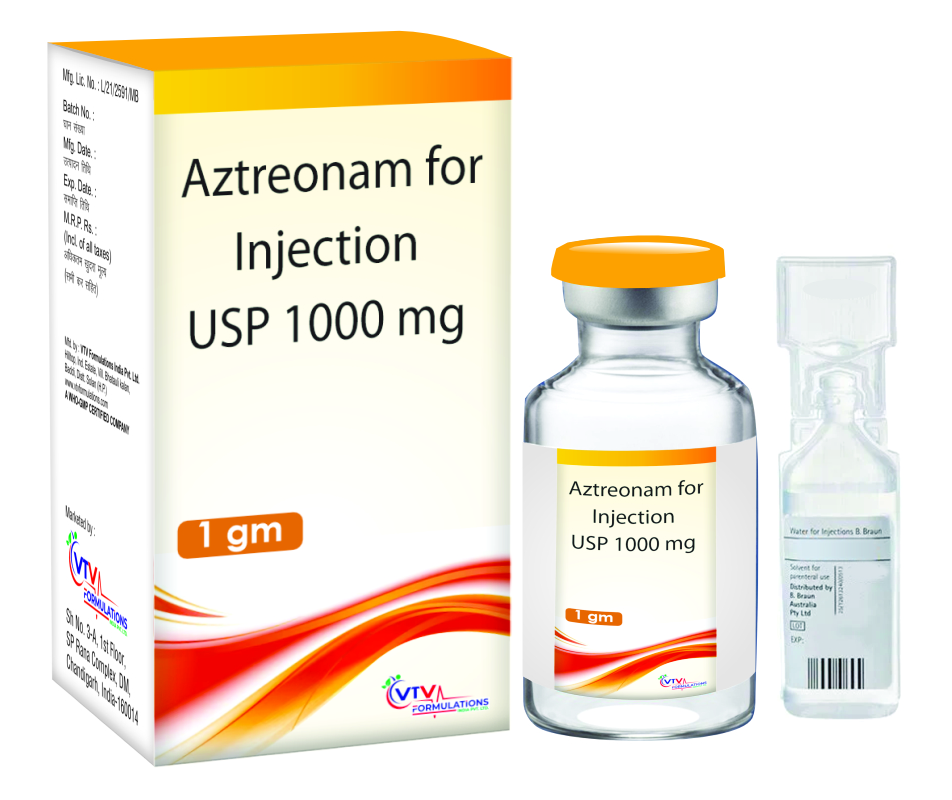

Select a manufacturer experienced in your specific injectable type—whether liquid injections, dry powder injections, SVP, LVP, oncology injectables, hormones, or veterinary injectables. Expertise ensures better results.

-

Raw Material Sourcing & API Quality

Ensure the manufacturer sources APIs from approved vendors and maintains strict testing protocols. High-quality APIs are essential for product performance, stability, and patient safety.

-

Batch Size Flexibility

Choose a manufacturer offering flexible batch sizes, especially if you are launching a new product and want to test the market before committing to large volumes.

-

Quality Checks & Testing Capabilities

A robust QC and QA setup is essential. Look for manufacturers who conduct sterility tests, stability studies, impurity profiling, and endotoxin testing to ensure quality consistency.

-

Packaging & Labeling Quality

The manufacturer should offer high-quality vials, ampoules, flip-off seals, carton designs, and labeling options. Attractive and secure packaging helps build brand trust.

-

Delivery Timelines & Supply Reliability

On-time production and delivery are crucial for maintaining your market presence. Always choose manufacturers with a proven track record of punctual dispatch.

-

Transparency & Communication

A reliable manufacturer maintains transparent communication regarding batch planning, material availability, testing results, and delivery dates, ensuring long-term business stability.

Step-by-Step Process of Working With a Third-Party Injectable Manufacturer

Working with a third-party manufacturer becomes much easier once you understand the complete production cycle and documentation flow. This clarity helps you plan more effectively, avoid delays, and maintain smooth coordination throughout the process.

The third-party injectable manufacturing process involves multiple stages that require careful coordination, documentation, and regulatory compliance. Understanding this workflow is essential because it helps companies maintain clear expectations and ensures smooth communication between both parties. When business owners know how the procedure works—from product selection to dispatch—they can manage their timelines better, prepare the required documents in advance, and monitor production progress with confidence. This also reduces the chances of misunderstandings or delays and ensures that the final product meets the required quality and branding standards.

- Product Selection & Finalization

The company first selects the injectable products it wants to manufacture. Manufacturers provide detailed product lists, market insights, and technical information to help businesses choose formulations with strong demand.

- Quotation & Cost Confirmation

Once the products are selected, the manufacturer sends a detailed quotation covering API cost, excipients, packaging, testing charges, and dispatch details. Finalizing the quotation early helps maintain complete transparency.

- Submission of Documents

To begin production, companies must submit essential documents like GST certificate, drug license, company profile, and authorization letter. These are mandatory for regulatory compliance and legal approval.

- Artwork & Packaging Approval

The manufacturer shares sample packaging designs and label artwork. Businesses can request changes until they are satisfied. Approving packaging carefully ensures strong branding and professional presentation.

- Manufacturing & Quality Testing

After artwork approval, production begins. Every stage—from filling to sealing—undergoes strict monitoring. QC and QA departments conduct sterility tests, stability checks, and physical inspections before releasing the batch.

- Final Product Release & Dispatch

Once testing is completed, the finished products are packed, labeled, and dispatched to the company’s location. Manufacturers also provide a Certificate of Analysis (COA) with batch details and test results.

Advantages of Knowing the Process

- Helps you plan product launches more accurately, ensuring your injectables reach the market at the right time and avoid stock shortages.

- Enhances coordination with the manufacturer, as you know exactly what to expect at each stage, making communication smoother and more effective.

- Reduces the risk of production delays, because you can identify issues quickly and take corrective action before they affect your launch.

- Supports long-term business development, enabling better forecasting, order planning, and gradual expansion of your injectable portfolio.

Final Tips & Detailed Conclusion

Choosing the right third-party injectable manufacturer is a strategic decision that directly impacts your company’s quality standards, brand reputation, and growth potential. Since injectables require sterile conditions and precision, it is essential to partner with a manufacturer who has technical expertise, quality certifications, and reliable output capacity.

Final Tips for Selecting a Trusted Manufacturer

- Prioritize quality over cost

Low-priced options may compromise sterility and quality. Always evaluate machine standards, certifications, and testing capabilities before finalizing any manufacturer.

- Visit the manufacturing plant personally

A physical inspection helps you understand the facility’s hygiene standards, machine accuracy, workforce training, and overall manufacturing environment.

- Check client reviews & market reputation

Manufacturers with strong reputations often deliver consistently high-quality products, maintain transparency, and ensure long-lasting business relationships.

- Start with a trial batch before a full order

A pilot batch helps you test product quality, packaging, sterility, and stability before moving to bulk production.

- Build a long-term partnership mindset

Consistent collaboration leads to faster production, better pricing, priority support, and smoother business operations.

Conclusion

In the rapidly growing pharmaceutical market, third-party injectable manufacturing offers enormous opportunities for both new and established companies. By partnering with the right manufacturer, businesses can reduce operational burdens, cut down investment costs, and expand product offerings with ease. The combination of advanced technology, skilled professionals, and strict regulatory compliance makes India a global leader in sterile injectable manufacturing.

A trustworthy manufacturing partner delivers more than just products—they offer expertise, reliability, scalability, and long-term support. This collaboration enables your brand to maintain consistent quality, meet market demands, and achieve sustainable growth. With high demand for safe and effective injectables, choosing a reliable manufacturer becomes an essential step in building a strong pharmaceutical business.

By evaluating certifications, infrastructure, quality systems, communication transparency, and production processes, you can confidently select a manufacturer who truly aligns with your business goals. When done correctly, this partnership becomes the foundation of your brand’s success and helps you create a powerful presence in the competitive pharmaceutical landscape.

Explore Related Blogs

Stay informed with our curated selection of similar blogs, offering expert perspectives on pharmaceutical trends, regulatory updates, and product innovations.

These articles are designed to help healthcare professionals, partners, and businesses stay ahead in an ever-evolving industry. Explore more to deepen your knowledge and make informed decisions.